1

/

of

4

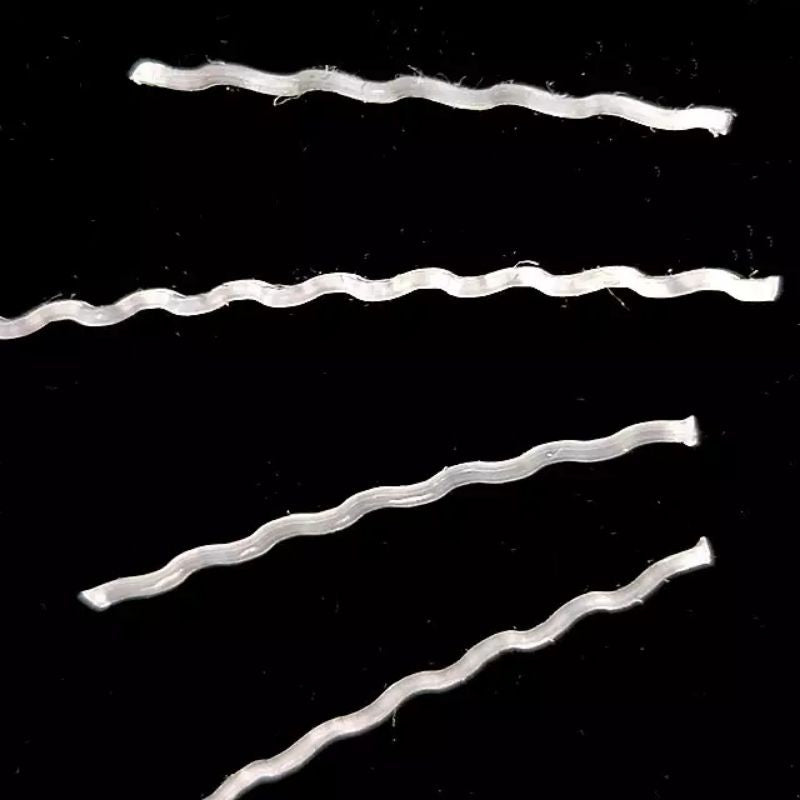

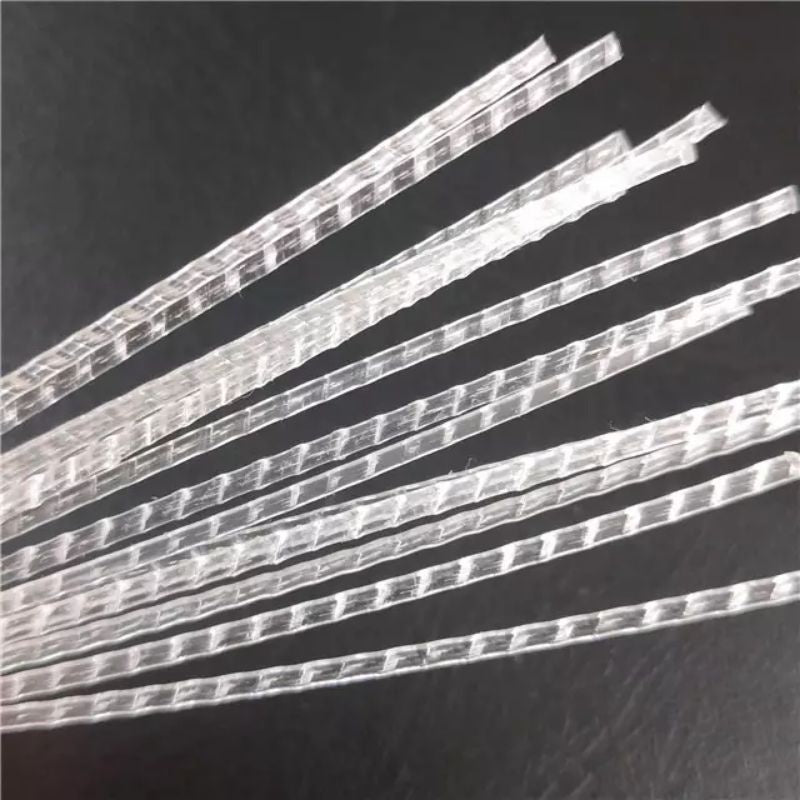

Polypropylene (pp macro fiber) Synthetic Macro Staple Fiber for Concrete

Polypropylene (pp macro fiber) Synthetic Macro Staple Fiber for Concrete

Regular price

₱679.00 PHP

Regular price

₱679.00 PHP

Sale price

₱679.00 PHP

Unit price

/

per

Couldn't load pickup availability

Polypropylene Synthetic Macro Staple Fiber for Concrete

***comes in 500grams or 1kg pack***

With 100% polypropylene as raw material,

PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation.

PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete. Because of special shape, PP macro fiber has good combination with concrete and strong bond.

1. Can reduce damage when happened earthquakes and other natural disasters.

2. To reduce fatal flaws in concrete

3. To reduce the leakage of concrete

4. To protect steel from corrosion

5. To improve the durability of concrete structures

6. Increase the wear resistance of concrete

7. Increasing the concrete crack

resistance, flexural strength, increased toughness of concrete, to extend the life of concrete binder

***comes in 500grams or 1kg pack***

With 100% polypropylene as raw material,

PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation.

PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete. Because of special shape, PP macro fiber has good combination with concrete and strong bond.

1. Can reduce damage when happened earthquakes and other natural disasters.

2. To reduce fatal flaws in concrete

3. To reduce the leakage of concrete

4. To protect steel from corrosion

5. To improve the durability of concrete structures

6. Increase the wear resistance of concrete

7. Increasing the concrete crack

resistance, flexural strength, increased toughness of concrete, to extend the life of concrete binder

Share