1

/

of

3

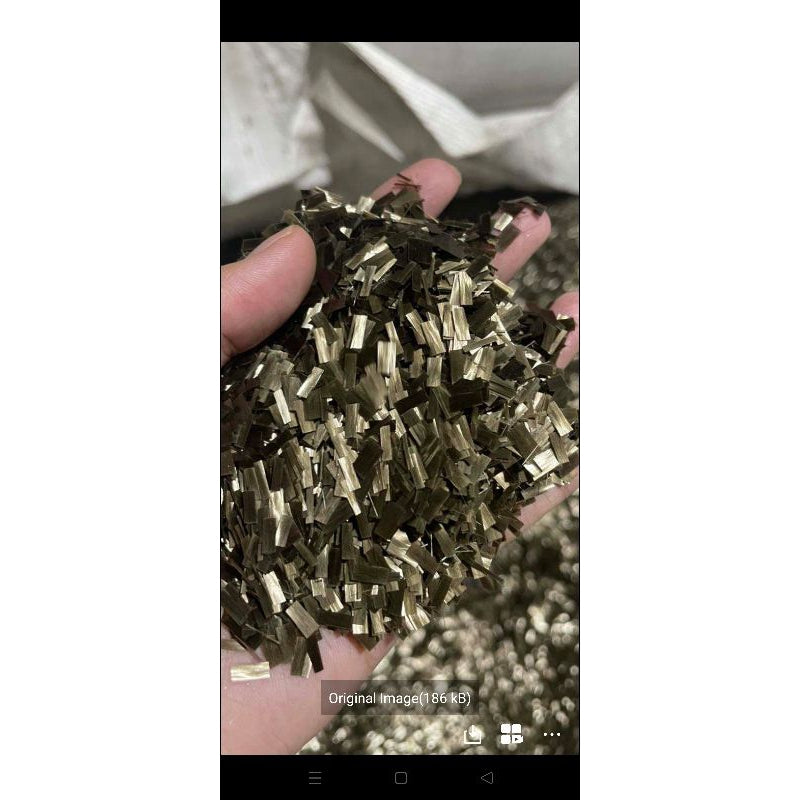

1kg Basalt or E-glass fiber high strength and high heat resistance fiber

1kg Basalt or E-glass fiber high strength and high heat resistance fiber

Regular price

₱2,499.00 PHP

Regular price

₱2,999.00 PHP

Sale price

₱2,499.00 PHP

Unit price

/

per

Couldn't load pickup availability

***OPEN FOR RESELLER***

Minimum purchase: 15kgs

Send message for inquiries...

Basalt fibers are continuous fibers made by high-speed drawing of platinum-rhodium alloy wire-drawing leak

plate after basalt material is melted at 1450 ~1500 C. Basalt continuous fibers have been widely used in fiber

reinforced composites, friction materials, shipbuilding materials, thermal insulation materials, automotive

industry, high temperature filter fabrics and protection fields. Because basalt fiber has the characteristics of

good acid-alkali resistance, high strength and high modulus, basalt fiber chopped yarn can be used in cement

concrete of road and bridge, Airport runway, dam and other projects. It has the advantages of superior performance and high economy. In addition, basalt fiber

has high temperature resistance and good combination with asphalt, which can significantly improve the high

temperature stability, low temperature crack resistance, water damage resistance and fatigue resistance of

asphalt concrete, and can greatly improve the service life of asphalt concrete.

TECHNICAL INFORMATION

Material: Basalt rock

Diameter: 18um

Length: 6mm,12mm,23mm,24mm

Specific Gravity: 2.68g/cm³

Tensile strength: 1850Mpa

Elastic modulus: 76Gpa

Elongation: 2.8%

Alkali resistance: Excellent

APPLICATION

Used in cement concrete or mortar concrete

Improve the crack resistance of cement concrete/mortar;

Improving the impermeability of cement concrete/mortar;

Improving the durability of cement concrete/mortar;

Improve the production efficiency and economic benefits of the project.

Used in Asphalt Concrete

Improve asphalt use efficiency and reduce flooding;

The dynamic stability is increased and the rutting resistance at high temperature is improved by more than 30%.

Reduce the generation of temperature shrinkage cracks and improve the low temperature crack resistance of

pavement by more than 40%.

Improving the ability of pavement to resist water damage;

It can improve the fatigue resistance of pavement by more than two times and prolong the service life of

pavement.

Minimum purchase: 15kgs

Send message for inquiries...

Basalt fibers are continuous fibers made by high-speed drawing of platinum-rhodium alloy wire-drawing leak

plate after basalt material is melted at 1450 ~1500 C. Basalt continuous fibers have been widely used in fiber

reinforced composites, friction materials, shipbuilding materials, thermal insulation materials, automotive

industry, high temperature filter fabrics and protection fields. Because basalt fiber has the characteristics of

good acid-alkali resistance, high strength and high modulus, basalt fiber chopped yarn can be used in cement

concrete of road and bridge, Airport runway, dam and other projects. It has the advantages of superior performance and high economy. In addition, basalt fiber

has high temperature resistance and good combination with asphalt, which can significantly improve the high

temperature stability, low temperature crack resistance, water damage resistance and fatigue resistance of

asphalt concrete, and can greatly improve the service life of asphalt concrete.

TECHNICAL INFORMATION

Material: Basalt rock

Diameter: 18um

Length: 6mm,12mm,23mm,24mm

Specific Gravity: 2.68g/cm³

Tensile strength: 1850Mpa

Elastic modulus: 76Gpa

Elongation: 2.8%

Alkali resistance: Excellent

APPLICATION

Used in cement concrete or mortar concrete

Improve the crack resistance of cement concrete/mortar;

Improving the impermeability of cement concrete/mortar;

Improving the durability of cement concrete/mortar;

Improve the production efficiency and economic benefits of the project.

Used in Asphalt Concrete

Improve asphalt use efficiency and reduce flooding;

The dynamic stability is increased and the rutting resistance at high temperature is improved by more than 30%.

Reduce the generation of temperature shrinkage cracks and improve the low temperature crack resistance of

pavement by more than 40%.

Improving the ability of pavement to resist water damage;

It can improve the fatigue resistance of pavement by more than two times and prolong the service life of

pavement.

Share